Sequential Injection is an ideal tool for automated monitoring and development of chemical sensors. The repeated automated calibrationruns allow evaluation of sensor stability, robustness (or lack of it), and vulnerability to fouling agents. SI also serves as a platform for design of reliable sensor systems, by providing automated sample conditioning, sensor calibration and even sensor regeneration.

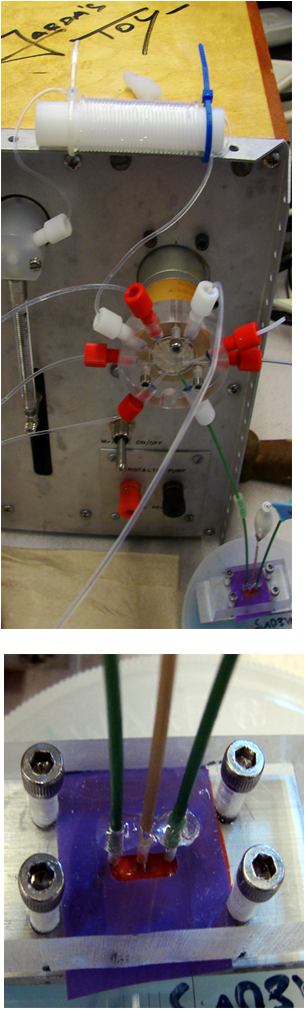

The sequential Injection instrument shown here, was designed for testing of a microfabricated amperometric glucose sensor. The sensor comprises a Pt working and Pt made counter electrodes, along with a Ag/AgCl reference electrode. Glucose oxidase is covalently immobilized on the working electrode, which is biased at +500 mV to detect the H2O2 produced by the enzyme in the presence of glucose. The sensor is incorporated in a thin-layer flow cell, which is connected to one of the ports on the multiposition valve. The remaining LOV ports are used for introduction of standard glucose solutions.

This setup is designed for automated, precisely controlled reaction rate stopped-flow measurements. The stopped-flow approach is especially useful for high sensitivity assays, since it allows the enzyme-generated H2O2 to build up, which increases sensitivity of measurement and improves the detection limit. This work is a part of a research project carried out in the group of Prof. Babak Parviz (University of Washington, Department of Electrical Engineering). performed by graduate students Angela Shum and Melissa Cowan.

Electrochemical Sensors: Testing and Development

2.3.15.